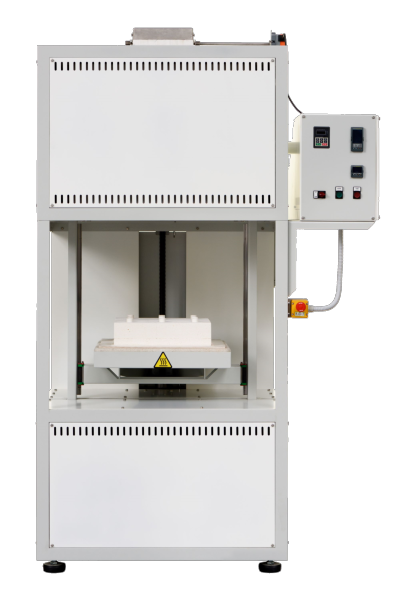

Admatec 450-CD-400 furnace

This furnace handles both debinding and sintering steps with only one machine, taking up less space in your working environment and saving time. Due to its large inner volume it is ideal for production of ceramic printing applications. The furnace has a chamber that can be moved through a mechanical system, enabling easy loading. With heating elements installed in four lateral walls, there is excellent temperature uniformity.

FR

FR