13/02/24

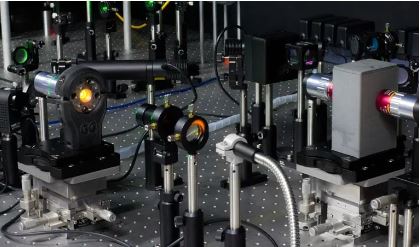

Many parts of scientific instruments require special design for their exclusive and complex shapes, 3D printing technology, with customizable characteristic, could be the first option to meet this demand.

3D Printing technology can bring smooth product development processes to Scientific Instruments industry,mainly from the following three aspects:

Some 3D printing materials have been developed to be resistant to high temperatures and pressures for ensuring that they are not deformed in the instrument.

Given that 3D printing is the construction of a three-dimensional object from a CAD model or a digital 3D model with material being added together, the prototype of scientific instruments can be customized and formed into any shape,based on 3D printing process,. The process can efficiently match the required accuracy and regardless of design constraints.

Weight reduction was achieved by redesigning the structure and replacing the original metal with a lower density 3D printing material. At the same time, 3D printing prototyping will greatly shorten lead time by quickly and accurately converting design drawings into physical objects and ultimately control costs.

Polymaker is reputational for its proficiency in material-extrusion based 3D printing area with comprehensive solutions.

Produced with Nano-reinforcement technology, the family deliver filaments with exceptional mechanical properties and printing quality. In particular. PolyMax™ PC-FR, an outstanding material in the research of flame retardant materials, could achieve V0 performance in the UL94 flame retardancy test and displays excellent toughness, strength and heat resistance. PolyMax™ PC-FR also has the advantages of reliability and ease of use. It is an ideal choice for scientific instruments production.

A family of Nylon/polyamide based filaments delivering engineering properties intrinsic to Nylon and ease of printing: PolyMide™ PA6-CF, a carbon fiber reinforced PA6 (Nylon 6) filament, has been the material of choice for the lab. With a heat deflection temperature of 215°C and its rigidity and strength, PolyMide™ PA6-CF proves itself as a very good candidate for many types of custom lab equipment. PolyMide™ PA12-CF, with excellent surface finish and dimension accuracy, featuring outstanding mechanical and thermal properties even after the moisture conditioning process, is also a good candidate material for producing jigs and fixtures in this industry. Besides, PolyMide™ PA612-CF, which has a significantly lower moisture sensitivity than that of nylon 6-based materials and a higher mechanical properties than general nylon 12 materials, also contribute to the industry.