3/09/23

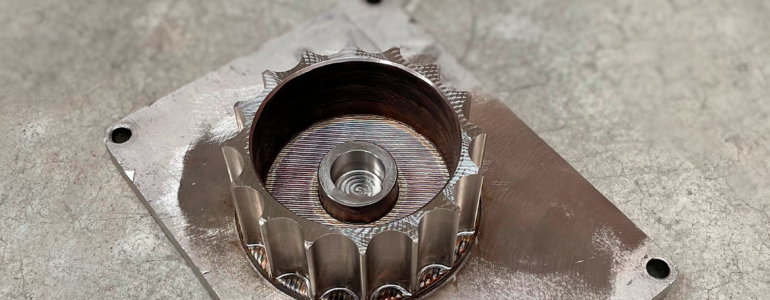

Belt sprockets are mechanical components transferring torque from a shaft to a belt in a belt drive assembly. These components exist in a wide range of sizes and can be employed in automotive and several different industrial fields.

SS17-4 PH is a martensitic precipitation hardened stainless steel capable of achieving high hardness and outstanding mechanical properties while offering excellent corrosion resistance. It is widely employed in the oil & gas, aerospace, energy, and defense industries. Typical applications include pump impellers, pipes, mechanical components and valves.

The sprocket could be manufactured either by CNC machining, scrapping about 60% of the mass of the initial steel stock, or by casting, with a high set up cost.

Additive manufacturing of the part via Meltio LMD process allows the optimization of the material used, while offering fast design iteration and manufacturing flexibility; all while preserving mechanical properties comparable to 17-4 PH in wrought form.

| Consumable | Quantity | Price | Cost |

| Material Shield Gas

Electricity |

1.62 kg

4.60 m³ 19.17 kWh |

34.15 €/kg

4.50 €/m³ 0.24 €/kWh |

55.32 €

20.70 € 4.60 € |

Print cost 80.62 €

| Consumable | Quantity | Price | Cost |

| Material

Shield Gas Electricity |

1.62 kg

4.60 m³ 19.17 kWh |

34.15 €/kg

2.38 €/m³ 0.24 €/kWh |

55.32 €

10.95 € 4.60 € |

Print cost 70.87 €