18/07/23

The brackets are fundamentally supported structures that are used to attach two different components while supporting one over the other. In an aircraft, these brackets are used on a wide range of applications, such as landing gears, fuselage airframe assembly, wings assembly, engine mounts, fuel tanks, and electrical wire installations.

Printing parameters for a small aircraft :

Printing parameters for a large airplane :

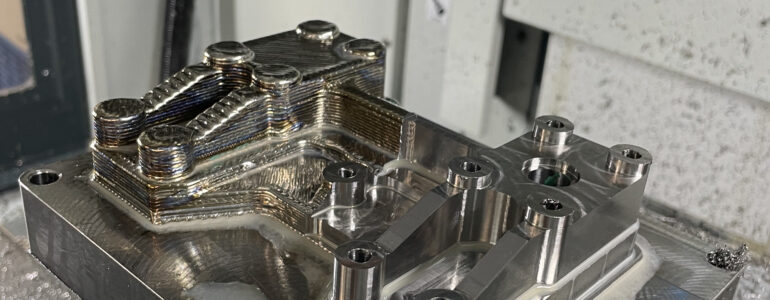

System: Meltio M450

System: Meltio M450Titanium is a lightweight and strong material that offers excellent corrosion and temperature resistance. Recent developments make titanium ideal for applications where aluminum alloys are too weak and stainless steel is too heavy.

CNC machining is the most traditional means of manufacturing brackets. For aerospace and defense companies, the focus is primarily on just-in-time (JIT) and on-demand manufacturing services offering low-volume production, therefore, using metal additive manufacturing technology gives the possibility of achieving it.

Global aircraft brackets market is projected to grow at a healthy rate over the next five years and the demand for lightweight brackets has been increasing rapidly in the aircraft industry.

Regarding the material, despite the fact that Aluminum is currently the most dominant metal used for the brackets, titanium and steel alloys have been increasing and the expectation is to keep witnessing high growth rates over the next two years, owing to a growing acceptance of 3D printed brackets. Steel brackets are costly and heavy and the introduction of titanium brackets made it possible to produce components that are lighter and less expensive.

The buy-to-fly ratio is simply the ratio of the mass of the starting billet of material to the mass of the final, finished part. The term originates from the aerospace industry and describes how much material is wasted in a manufacturing process.

For this part, the BTF ratio is close to 3 which means that almost 65% of the material is being wasted.

Cost Scenario 1: Gas Installation using a 50l bottle (4.5 €/m³)

Cost Scenario 2: Gas Installation using liquified gas (2.38 €/m³)

Cost Scenario 1: Gas Installation using a 50l bottle (4.5 €/m³)

Cost Scenario 2: Gas Installation using liquified gas (2.38 €/m³)