4/01/24

The Comet 1000, a variant of Bradford Space’s electrothermal propulsion system, is helping maneuver more than twenty satellites in Earth’s orbit. Discover how metal 3D printing delivers the durability needed to succeed in this challenging environment.

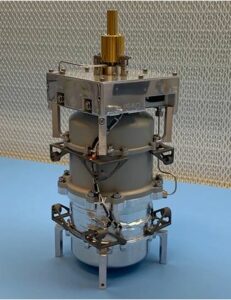

When it comes to rocketry propulsion systems, Bradford Space does things a little differently — especially in the case of its electrothermal Comet series. Designed for small satellites, each unit uses water as a propellent rather than traditional fuels, making it easy to run and operate, all while balancing cost and performance.

But while its fuel may differ from traditional systems, the challenges the Comet faces from its environment do not. Bradford Space and its customers need each part to be durable, lightweight, and able to handle the stress that comes from entering orbit.

Among these parts are the unique brackets used to connect the Comet series to a variety of satellites. Originally designed for additive manufacturing in the United States, Bradford Space required a local manufacturer who could produce them in Europe while maintaining the necessary standards. In 2021, they turned to Materialise to do so.

Knowing the bracket’s role within the system and the stressors they face, the solution was clear: metal 3D printing in titanium. With the Metal Competence Center in Bremen at their disposal, Materialise engineers worked together with those from Bradford Space to begin production.

“Because the design is driven by our customers’ requirements, mostly related to how it interfaces with the satellite, we began just by optimizing it a little bit,” explains Edder Rabadán Santana, Project Lead for the Comet Propulsion System. “These requirements make the bracket’s shape too complicated for traditional machining and too costly for other manufacturing methods. That’s the main reason to go with 3D printing.”

Similarly, titanium was the obvious choice for Edder and his team. Like in any space project, weight saving is crucial, but it can’t come at the expense of durability. The challenging environment brings a lot of stressors that the Comet has to handle.

With water as its primary fuel source, the Comet system faces less regulatory pressure than traditional systems, but quality control remains crucial. Bradford qualifies all its parts to ensure they fall within a strict threshold through rigorous environmental testing that uses shock, random, and sine vibration according to NASA’s General Environmental Verification Standard. The team also monitors thermal cycling by alternating the system between its minimum and maximum operational range.

“The main purpose of these tests is to simulate the launch vibrations, so they can be quite random — a combination of shaking and acceleration,” explains Edder. “Earlier in the development phase, we ran qualification tests where the vibrations were more violent. Now that we have over 100 parts in orbit, we simply run much lighter acceptance tests on the parts we receive. What matters is that every test meets NASA standards.”

To date, more than 25 of Bradford’s Comet propulsion systems are circling the planet onboard Earth observation satellites — each carrying four 3D-printed titanium brackets — clearly indicating that the parts perform as expected. However, as with any project, engineers from Materialise and Bradford Space are still working together to optimize them further.

“Our engineers and the engineers from Materialise have worked together to improve the bracket’s end result as much as we can,” explains Edder. “We want to make them as flat as possible to make integration easier. The team is very helpful and overall, I think the process has been very smooth.”

With the Comet series featuring two 3D-printed parts, it’s clear that Bradford Space is on board with using the technology where appropriate. The advantages are clear for Edder and its team — but only when the parts are designed for AM.

“I think 3D printing is very attractive for any industry, especially for aerospace,” he tells us. “It depends on the product or the business case, of course, but if it’s smart to make a part with 3D printing, I think most companies will go for it now. In general, it helps speed things up, and the cost is normally comparable — or can even lead to savings. Sometimes, like with our brackets, the engineers create a design with geometries that are too complex for traditional manufacturing methods, and then the interest in 3D printing is always there.”