8/11/22

The Korea Aerospace Research Institute (KARI) contributes to developing the national economy and enhancing people’s lives through new exploration, technological advancements, development, and dissemination in the aerospace science and technology field. Recent developments in aviation structure weight reduction technology required a software solution that gave them complete control over their new lattice design — while enabling them to print the STL file without disrupting the lattice’s structural integrity.

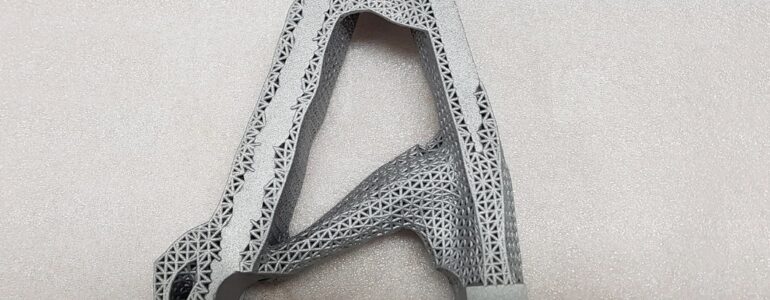

Our design for additive manufacturing (DfAM) knowledge and Materialise 3-matic helped the team optimize the part’s topology for a smoother surface. And concurrently, print a structurally stable lattice file to verify the model’s simulation results. This led to the production of a lightweight, reliable metal 3D-printed part.

Create a topology-optimized lattice structure and make it printable in the design stage.

Dr. Kim Tae-wook works in KARI’s Aeronautics Research Directorate and researches ways to reduce the weight of parts used in landing gear, aiming for higher accuracy and reliability. In a previous study, Dr. Kim converted the test results from the Altair® OptiStruct simulation technology into a topology-optimized 3D model and successfully printed the part with an external service bureau. The following study involved weight reduction, where he used advanced features in OptiStruct software to reduce the weight even further, based on the previous set of results.

The new model utilized a lattice structure to minimize material usage and, consequently, lower the overall weight of the part. However, Dr. Kim ran into two issues when he wanted to repeat the simulation of this converted model to verify the reliability of the design’s new lattice feature. The first was optimizing the topology, smoothening the overall surface while retaining the new lattice structure. And the second was creating a printable STL file.

To change the lattice-inspired raw data into a refined, printable file, Dr. Kim needed a software solution that gave him full control of the lattice structure. He also required a DfAM process to support him that’s normally recommended by a 3D printing (3DP) design expert. But handling the data with conventional CAD software was not possible in its current state, and the service bureau was unable to provide a solution.

DfAM and Materialise 3-matic training on AM’s optimization processes.

When Dr. Kim met and discussed his requirements with Materialise, he thought it would be possible to print out the new lattice structure designed in OptiStruct and convert it into STL format. In reality, however, another issue appeared. It’s impossible to print an incomplete or rough topology-optimized STL design with an open volume mesh structure. The exposed lattice framework would converge with the support structures needed to produce the part, increasing the likelihood of fractures during the support removal process. This was the main concern of the service bureau and the company’s reluctance to accept this print job. However, throughout the consultation, Kim Dongho, a Design Engineer at Materialise, explained the DfAM process and advised him of the importance of AM’s editing and modeling optimization processes.

Dongho is a Materialise 3-matic product expert and associated with our Design and Engineering division, so he’s used to finding solutions to challenging problems. He came up with a way to navigate the printing issue by enhancing the design while also considering the build orientation and calculating the surface area of the lattice using 3-matic. He advised Dr. Kim to use a simple yet clever solution to overcome the interaction between the support structures and lattices. Namely, to create a thin, solid layer in the downfacing areas of the part. This approach ensures that only a minimal amount of material is added to the part while solving the printability issue. (A similar technique seen in our 3DP spider bracket collaboration).

Dr. Kim decided to purchase 3-matic with dedicated training sessions, as he wanted to quickly get through the initial learning curve and focus on the task at hand. Plus, the Materialise team provided customized sessions and guided him from the preliminary plan to the final product.

An AM-optimized and print-ready lattice design — resulting in a reliable, lightweight 3DP part for landing gear.

Using Materialise 3-matic, Dr. Kim managed to master the lattice structure and STL printing capabilities for his model. Dr. Kim and the Materialise team successfully converted the data and avoided the risk of lattice breakage by generating downfacing surfaces to protect the lattice structure. And to prevent the support material from fusing with the lattice. As a result, Dr. Kim and the KARI team could realize the simulation into a genuine part with DfAM.

KARI’s metal 3D-printed aerospace part with lattice structure is lighter and more reliable than the previous version.

Using a dedicated 3D modeling tool and technical support from our AM experts enabled KARI to reduce unnecessary experimentation via trial and error and establish a more straightforward design approach. And our unique knowledge and experience in metal 3DP helped the team enhance the part — with a design optimized for AM — increasing its printability.

KARI established a more advanced approach for their lightweight structure, a critical element for parts used in the aerospace industry. Dr. Kim and his team verified and repeated the finished 3D model in the simulation: completing and printing the actual parts based on data obtained during the process. The KARI team was so impressed with the results that it’s now conducting another project using 3-matic. Dedicated 3D modeling software is an accessible tool for various applications. And combined with DfAM expertise, 3DP is a desirable solution in aerospace, demonstrating qualities that improve reliability and weight reduction for many use cases.

KARI was so impressed with the metal 3D-printed part that the Aeronautics Research Directorate is now conducting another project using 3-matic.