22/02/22

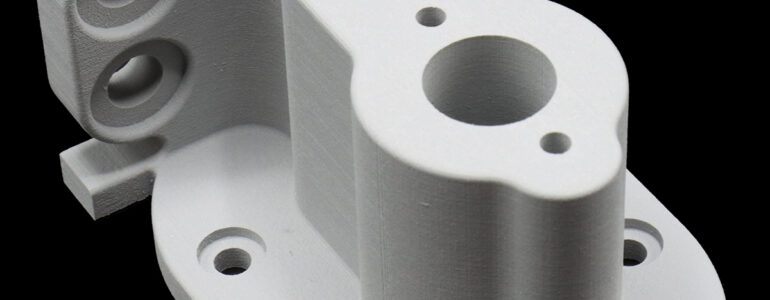

Rethink how industrial automation equipment can be designed and manufactured. With the Inkbit Vista system, traditionally machined and molded assemblies can be simplified and consolidated for improved performance and reliability. Integrate pneumatic circuits and introduce soft contact surfaces while streamlining production, minimizing tooling, and reducing replacement part inventory.

High production throughput

Large build volume (500 x 250 x 200 mm / 19.6 x 9.8 x 7.8 in)

Consistent, reliable parts due to in-process closed-loop feedback

Low labor support removal process