17/06/23

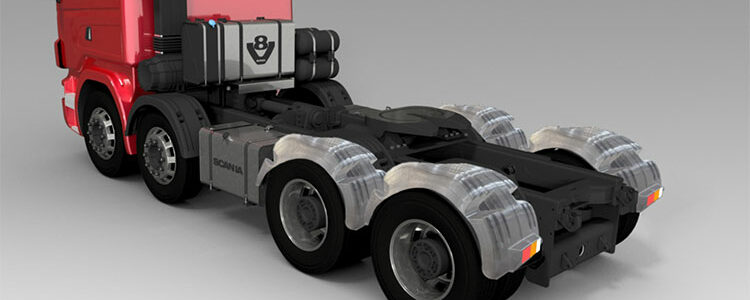

Installation Results (Rendering)

Compared with FDM 3D Printing, IEMAI3D Pellet 3D Printing Technology has the advantages of low cost and high efficiency. The fenders are printed with PETG modified material, which takes 30 hours for a single fender, weighs 10 kg, and costs about RMB 360. IEMAI3D Pellet Printing Machine FAST-JET-1500 has a large printing area of 1.5 meters in length, width, and height; an extrusion head temperature of 400°C, and a three-zone temperature screwhead, full sealed cavity, and self-developed automatic feeding technology. Creating a great environment for 3D printing for wide range of pellet materials. The automatic feeding technology has created excellent hardware conditions for pellet moulding of various materials. At the same time, IEMAI3D’s material engineering team provides stable process parameters for different pellet materials, which has laid the foundation for direct pellet printing.