24/11/20

Immersion in the heart of the G’Well workshop to discover its know-how and

the most precious secrets of its tailor-made creations, set with a dose of ethics.

A craftsman jeweler for more than 30 years, and a graduate of the Arts Joailliers de Valence, Dominique Giuliani studied in the great Parisian houses of Haute Joaillerie and Haute Couture before setting up on his own in the 2000s, to design the collections of French and Italian jewelers. Passionate about gems, he then embarked on stone trading before creating, in 2006, the G’Well workshop and his first jewelry collection. For 14 years, the jeweler has brilliantly combined a love of stones, virtuoso know-how, technical prowess and innovations.

8 trades under one roof

8 trades under one roofIn the heart of the Gironde, the family cradle of the manager, all the knowhow of the house is combined. For optimal control at each stage of production, the different professions work together: computer graphics artist, 3D designer, founder, worker-jeweler, crimper, polisher, engraver and gemmoogue. Initially five, around twenty people now work in a closed network to produce these medium and high jewelry pieces. Between creation and manufacture, each piece of jewelry is taken in hand by a team made up of a production manager, two technical coordinators, ten jewelry workers, two gem-setters and a founder. The manufacturing process is punctuated by three quality controls, systematically traced, and by the interventions of the stone department for the choice and sorting. G’Well has chosen to retain a gemological department to meet the sizing requirements of setting stones. French jewelry requires perfect knowledge of the four criteria qualifying diamonds and those of colored stones. Through its experience, skills and partner laboratories, G’Well has the means to respond.

« In an eco-responsible approach, we have implemented concrete sorting and recycling actions »

The jewelers’ workshop on the left and the gem-setters on the right.

« By modernizing its processes, G’Well is giving itself the means to meet the major artistic challenges generated by creativity and the search for exceptions »

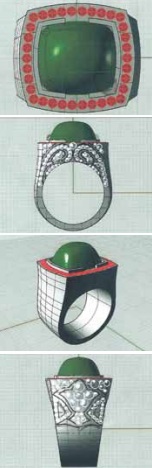

Fleur de lys,

signet ring set

with an emerald cabochon

9.3 carats and diamonds.

In accordance with the rules of the art, the G’Well workshop respects the know-how

of the French manufacture of jewelry, as well as all the laws and standards governing the sector.

A practice which gives it the privilege of applying the Joaillerie de France hallmark to all its creations

since 2014. The RJC – Responsible Jewelery Council – certification obtained by the house in 2016,

also attests to its responsible environmental and social practices.

« Our organization allows the workshop to provide its customers with a very high level of confidentiality »

Captivated by artistic challenges and technological innovations, Dominique Giuliani gradually equipped the G’Well workshop with high-tech equipment : latest generation CAD-CAD software, 3D scanners, 3D printers … a meeting point between tradition and modernity, the foundry line compatible with all alloys – gold, silver, platinum – allows the workshop to be autonomous and above all reactive. The technology is there, without replacing humans. In fact, the team of young jeweler workers, all trained in traditional French jewelery techniques, is supervised by experienced people whose know-how is well established. Responsible for the most subtle finishes, their skills are also based on an excellent knowledge of the history of the art of jewelry and of the designers who have marked their time. The G’Well management participates in this made in France know-how, passed down from generation to generation, and acquired from the great houses, institutions and experts of French jewelry.

Pendant Gorgone,

set with a tanzanite of

19.8 carats and

480 diamonds.

For its state-of-the-art high-tech equipment, the workshop relies on Solidworks, Rhino, Solidscape, and OGI systems.

The G’Well organization is based on the principle of interactivity between the different departments and poles of activity. An operation that naturally generates exchanges, ideas and a strong ability to interpret “the aesthetic of the invisible” through taste, style and technical subtleties. Indeed, each piece of jewelry poses technical problems that must be solved by inventing and creating. An example, this Lasso Necklace commissioned by an actor of Swiss jewelrywatchmaking in January 2015. After a few hours of puzzles and ingenuity, and by combining different enamel systems, the G’Well team took up the challenge. technical challenge of the jewel without altering its aesthetic aspect. The result: two “ribbons” stitching together over the neck and articulating with enough flexibility for a most perfect pose.

Collier Lasso,

set with a monochrome

pink sapphires cut

pear 11.61 carats

and diamonds.

The professional links established between G’Well and laboratories such as GIA, HRD, SSEF, and GRS, attest to the qualitative approach of its stone department.

G’Well Contacts

Phone : +33 5 57 34 23 17

Direction Production : contact@gwell.fr

DAO-CAO : protoconception@gwell.fr

Direction Pierres : stones1@gwell.f