8/02/22

Traditional Methods

Design flexibility, lower cost and faster turnaround.

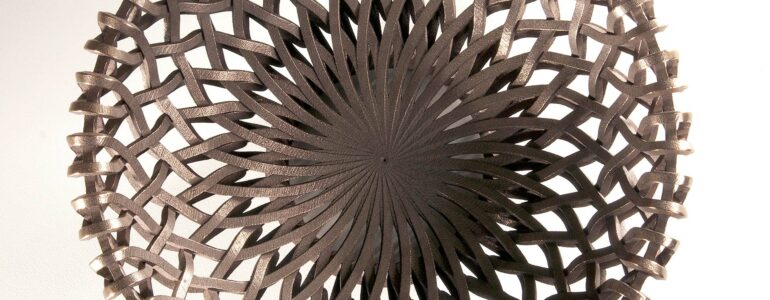

ExOne’s 3D metal printing technology was used to print single-piece strainer plates.

Additive manufacturing offers the ability to optimize part design; there is no cost for complexity.

ExOne® offers digital part materialization using threedimensional printing to create full-form parts directly from CAD data for a variety of applications. The technology is capable of a geometric complexity unachievable with conventional manufacturing methods.

Components produced by ExOne can reduce weight, integrate multi-piece assemblies, enhance product functionality and significantly reduce lead times for prototype and short-run production.

ExOne operates facilities across the Americas, Europe and Asia.

ExOne’s revolutionary 3D printing process allows levels of design freedom and customization that are either too expensive or impossible to produce with traditional manufacturing techniques. ExOne can create truly custom metal pieces for virtually any art or decorative project, in quantities as small as one.

Personalization

PersonalizationRequests for monogram, text, or other 3D graphic can typically be accommodated for a nominal fee depending on complexity.

Manufacture of a catalog product in an alternate size than is currently offered. Due to the nature of the process, these changes are easily accomplished, without the need for redesign.

This requires creation of an electronic 3D model using special design/engineering software. Customers have the option of providing the 3D model or may contract ExOne’s design services to develop a model based on the client’s design/sketch.