8/07/22

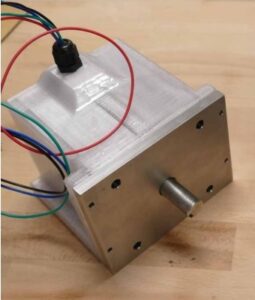

We wanted to make a protective box that would seal stepper motors, which we did, and then manufactured cover covers for our electric motor solution.

The modeling of the parts was carried out in a fairly traditional way using the Solidworks software.

We used PETG for its properties of mechanical resistance, its hydrophobic nature and its ease of implementation on large format. Post-treatment phases, in particular the addition of epoxy resin for sealing, and paint for the covers, are then applied to our parts.

(LAYER THICKNESS, POSITIONING, FILLING RATE, ETC…)

Wishing to produce large parts, we focused on an optimized printing time so as to be able to reduce their production cost, while having a quality corresponding to our expectations. Thus, 0.8 mm diameter nozzles were chosen to print the covers with a layer thickness of 0.5 mm, then 0.6 mm diameter nozzles for the stepper motor cases, printed in 0.3 mm thickness of layers.

The build volume of the Strateo3D allowed us to print each cover at once, in a single extrusion, on the plate. Regarding the motor boxes, we printed four of them on a single plate.

Printing a stepper motor housing takes 14 hours, the side covers take 22 hours each, and the top cover is two pieces that print in 9 hours, and it takes 82 hours to get the front cover.

The main advantages that led us to choose the Strateo3D to produce our parts are its reliability, its printing quality and the fact that it allows the production of large-sized parts. Its speed of execution was also a determining factor.

(TIME, COST, ETC…)

We immediately considered 3D printing for the production of these parts because it is a manufacturing process that allows us to obtain greater flexibility as well as controlled costs without having to go through a mould.

Robinson Serre, Bluenav mechanical engineer