23/02/24

Marine architects and designers feel the need to have new technologies to produce more complex and customized parts, according to yacht customers’ desires. Heron AM can be the solution for yacht and shipbuilding companies, enabling them to manufacture superstructural parts such as yacht grids, for one-of-a-kind or small series productions.

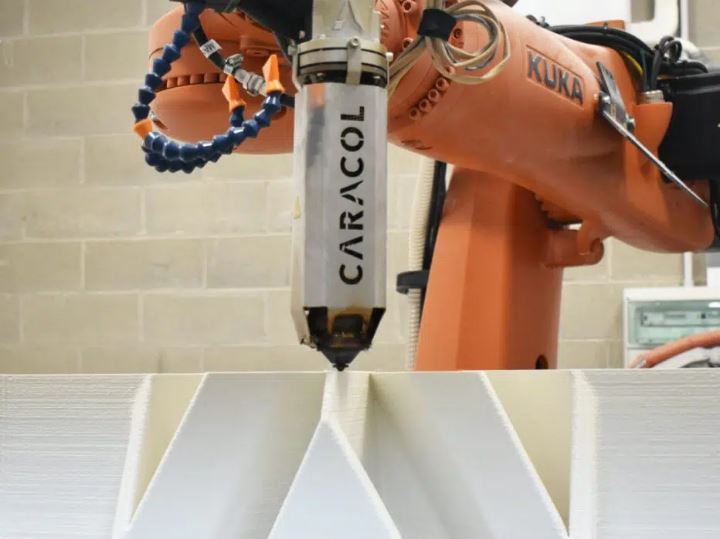

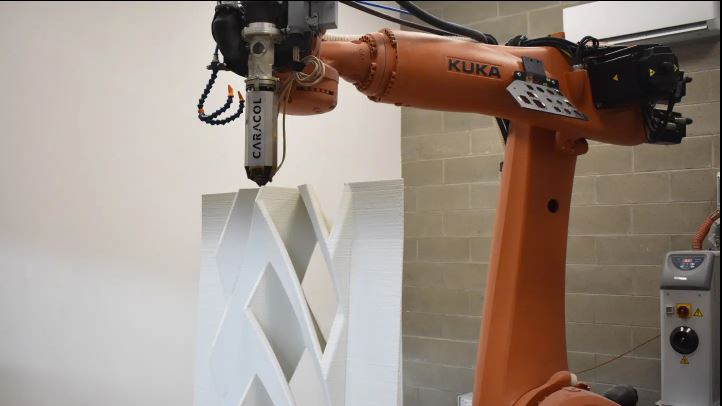

From several points of view, air grids are an interesting application for Additive Manufacturing: their designs are complex, not-flat geometrical shapes; and the engineering process in traditional manufacturing still entails hand-made lamination using molds and fiberglass or metal sheet working as laser cutting, bending, machining. These needs can be satisfied by working with a technology like Heron AM, that leverages its proprietary software and the robotic arm’s 6-axes, to extrude at various angles, also printing suspended surfaces and hollow, light, and intricate geometrical forms at 45°.

01 Yacht Superstructures – Air Grids

02 Yacht Superstructures – Air Grids

Applying Caracol’s LFAM system Heron AM to this production means having the opportunity to design innovatively shaped structures with light-weight geometries without the need for molds or jigs, which finally leads to overcoming the typical time and cost constraints of the traditional manufacturing technologies while guaranteeing its quality standards.

Additive Manufacturing is also a sustainable solution if considering its environmental impact. In the case of these air grids’ production, ABS is mixed with 30% glass fiber. At the same time, the process optimization, combined with the extrusion high rate, leads to up to 50% improved lead time. Finally, the digital design files are saved and can be adapted to future maintenance and spare parts needs. The overall effect for boat builders is a significant cost reduction of up to 70% according to production volumes.

PROJECTS FACTS & FIGURES

Production specs:

Savings:

Article from our partner Caracol