21/11/23

Additive Manufacturing is disrupting the industrial landscape – and, specifically, 3D printing of large-format components (Large Format Additive Manufacturing – LFAM) now represents a fast-growing niche market, with increasing demand from various sectors such as aerospace, marine, architecture, and design. Caracol is among the first and most renowned technology providers of large-format composite pellet-based additive manufacturing systems.

Quality represents one of the greatest challenges for AM technologies: always guaranteeing the required functional performance and a high level of accuracy on final products is crucial to enable these technologies’ adoption, especially for advanced and highly regulated applications. Continuous monitoring of process variables, machine status, and working environment conditions (e.g. temperature and humidity) all contribute to ensuring stability, repeatability, and efficiency of the production cycle.

Caracol has been working assiduously to introduce this technology to its Heron AM systems, providing the highest degree of reliability and repeatability for its process. Monitoring systems usually detect possible threats and unexpected behaviors, performance issues, or non-compliance problems in a fully automated way, through a wide range of sensors installed on the machinery. By using algorithms and exploiting Machine Learning, data is extracted, stored, and displayed through real-time insightful visualizations. The automatic detection and signaling functions lay the foundation for in-line adjustments of process parameters. The automatic modification occurs while the printing process is taking place, to mitigate or correct the defect itself and thus preventing the generation of any production waste or non-conformities. In addition, the positive impact of monitoring and control systems, integrated into industrial 3d printers, results in significant optimization of the resources employed in the process. The reduction of the costs related to ‘poor quality’ leads to less waste while lowering the raw materials usage, machine and man hours needed, and time spent on inspection and post-production of defective parts.

In this scenario, Caracol worked on the project RAMICoS – Intelligent Control System for Robotic Large Scale Additive Manufacturing System, a project financed by the Italian Ministry of Economic Development. Through the collaboration with MADE Competence Centre and Politecnico di Milano, the company aimed to achieve several objectives by the end of 2023:

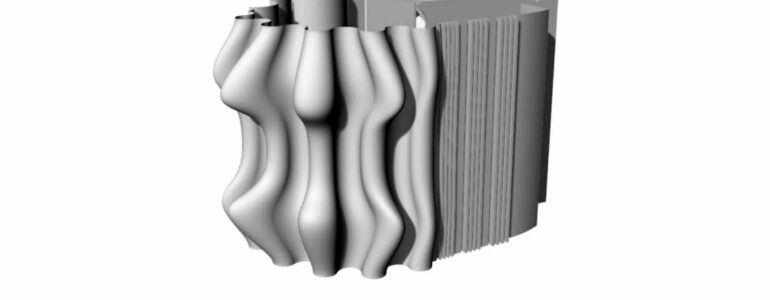

For the project’s execution phase, Caracol’s LFAM system Heron AM was equipped with about ten sensors to track different parameters, including the system and its components’ electricity consumption, the working environment’s temperature and humidity, the extrusion temperature, possible shocks and vibrations to the extruder, the energy consumed by the extruder’s screw motor, and many more. By registering all these signals and collecting data, a digital twin of the printed component was generated, enabling the identification of the areas affected by problems with material deposition. Moreover, Caracol developed machine-learning algorithms for automatic defect identification and alarm generation.

The use of such tools can positively impact manufacturing processes and companies in several ways. First of all by facilitating the work of operators as decision-making support, it helps the duties of quality and maintenance departments by quickly identifying the root cause of problems, and it helps forecast the use of resources for production such as energy consumption by operational managers.

Bringing this project to completion has opened a phase of further developments for Caracol. The company wants to implement these smart 3D printing solutions to ensure clients can benefit from being promptly notified of any occurring printing issues, and put into place automated corrective actions. The ultimate objective for Caracol is always ensuring the best quality of the printed components while minimizing costs and maximizing process efficiency.