21/09/23

Save time and money with lightweight, 3D printed factory tooling produced on-demand

REDUCE LEAD TIME BY 90%

Minimize logistics by manufacturing jigs and fixtures in-house.

UP TO 94% CHEAPER TOOLING

Cut tooling costs with digitized production and reduced assembly.

DIGITAL INVENTORY ON DEMAND

Print tools on demand from a digital inventory to save time and storage space.

Production aids and inspection tools are expensive and slow to manufacture, typically outsourced and requiring many design iterations prototyped over 8 to 10 weeks. Handheld jigs can be heavy and cumbersome to use, while complex fixtures may require extensive assembly and costly components.

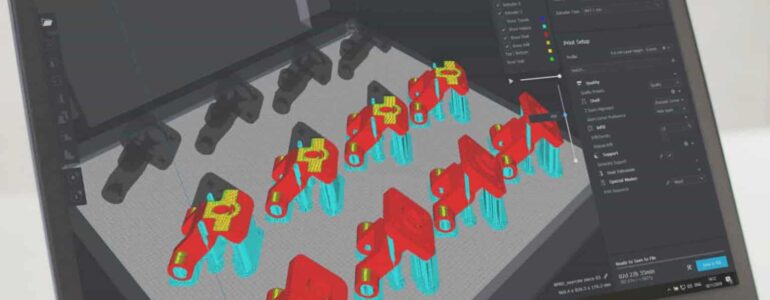

BigRep 3D printers are a game-changer for virtually any factory tooling aid from production and assembly to quality assurance. Produced in-house and on-demand, 3D printed tooling drastically simplifies logistics and lead times, while significantly cutting costs up to 94%. Lightweight, strong, and ergonomic 3D printed factory aids are customizable and multi-functional.

Ford embraced additive manufacturing 30 years ago and now relies on BigRep for large-format 3D printing to produce full-scale jigs and quality assurance tools in one single piece. For Ford, the cost savings are huge, as their BigRep machine paid for itself after just the first few prints.

Walther Automobiltechnik (WAT) makes the most of their BigRep 3D printer by producing all kinds of factory tooling and production aids. From inspection fixtures and tool holders to mistake-proofing, WAT had thoroughly embedded additive manufacturing into their production processes and has seen massive benefits thanks to BigRep.

Design the 3D model (export an STL or OBJ file)

Design the 3D model (export an STL or OBJ file)