28/08/23

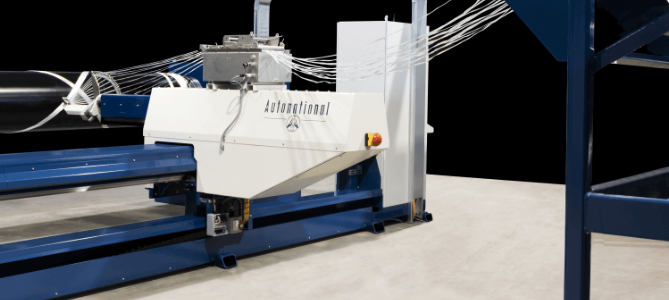

For Mitaş Composites, we delivered a high and medium capacity semi-automated production line for the production of composite light poles and utility poles. The company has invested in a filament winding production line to manufacture composite utility poles. The automation-ready equipment, with a manufacturing capability of 1,000 poles per month, enables the group to grow and diversify its existing product range. Our equipment is suitable for epoxy en polyester resins, and glass fiber or carbon fiber applications.

Autonational provides its customers a total ‘unburden’ service on composite pole production. Over the years, we’ve grown our competencies and knowledge of composite pole manufacturing into highly valuable datasets.

Utility poles: they’re everywhere. Electricity poles, light poles, and sign poles are widely used for infrastructure worldwide. Usually, these poles are made of steel, wood, or concrete, but this comes with many disadvantages. Not only can these poles be heavy, but they can also corrode, which requires toxic chemicals to prevent and combat this. Therefore, the present time calls for new materials for such well-known products.

Making these utility poles out of composite has many advantages over other materials. The poles are strong and lightweight and have a longer lifespan than poles made of different materials. Autonational, therefore, provides automated and semi-automated production lines and machines for the production of composite utility poles. Depending on your product design, purpose, and the required capacity, these poles can be manufactured in custom lengths and diameters and with a conical, straight, or combined shape. To stay ahead, we research, test, and work to produce composites that can be easily recycled, such as biocomposites, while retaining all the benefits of composite poles, such as:

Autonational provides R&D services to develop the utility pole or any other composite product you have in mind. We can produce prototypes or small series for trials, testing, or certifications, while your machine or production line is being developed. This way, we can make your ideal machine or production line and react quickly, allowing your production to start as soon as possible. In addition, we can educate your operators during the assembly phase to learn to work with the winder and know the crucial aspects of high-quality composite production.

Autonational treats every customer as a partner. By listening and collaborating, we find the best solution together.